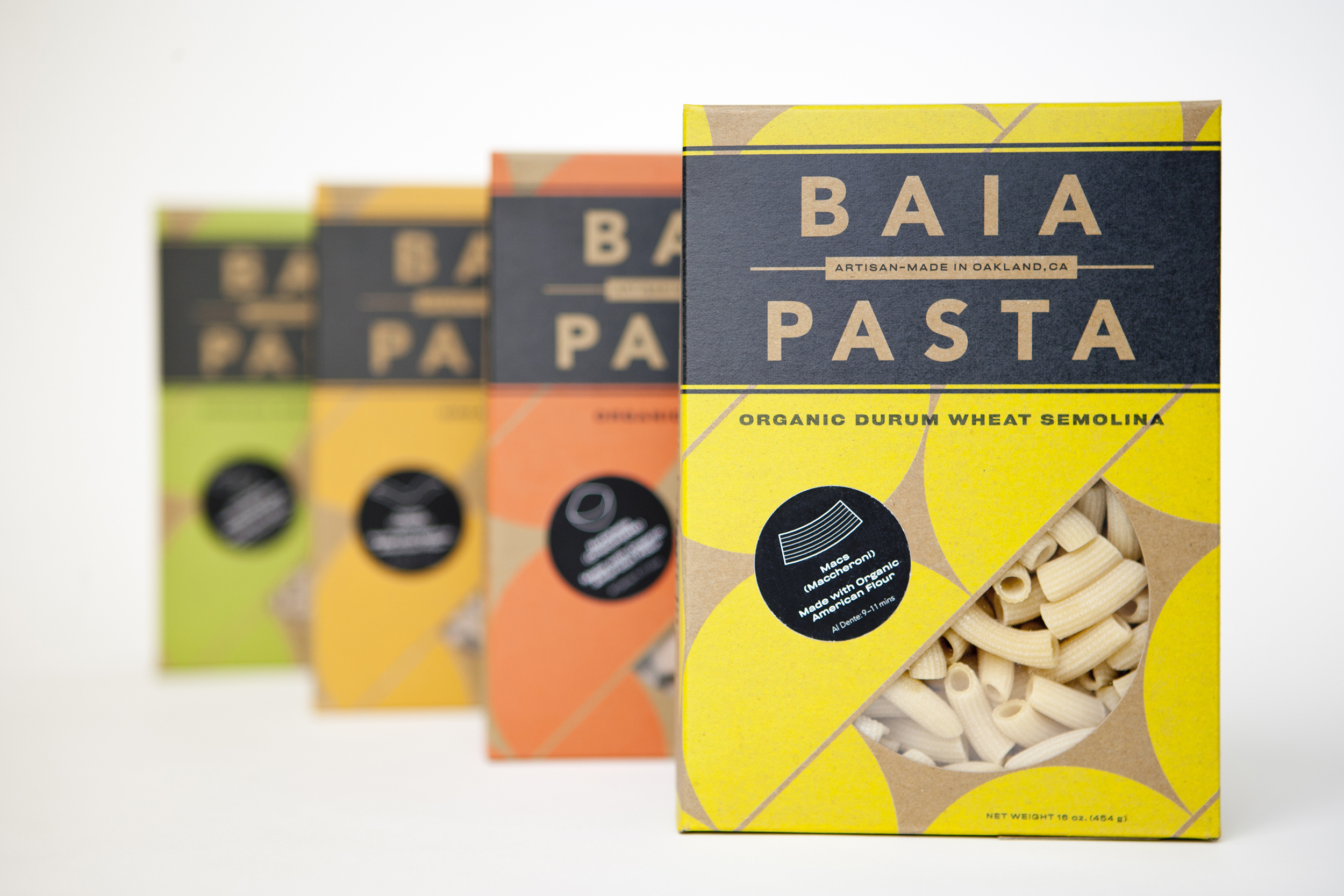

Eating the carefully crafted creations of Baia Pasta, an artisan operation based out of Jack London Square in Oakland, will whisk you away to the pasta’s roots in Piemonte, Northern Italy, where “food is passion, a language, an emotion; food is everything.”

Co-founders Renato Sardo and Dario Barbone are guided by the principles of the Slow Food movement — Renato served as Director of Slow Food International for 8 years and helped found Slow Food USA — which compel them to use the best organic, American-grown grains available to produce a variety of delicious short cuts. And they just made their commitment official, earning USDA Organic certification!

Unfortunately, even in the world of high quality, artisanal pasta making, there are unforeseeable errors in production that can affect the aesthetics of the pasta and result in food waste.

I recently spoke at greater length with Dario about their operation, inspiration, and journey. Read on below to learn more about what “ugly” pasta is, how it happens, and how Baia Pasta got started.

Q: What makes Baia Pasta special?

A: Baia Pasta has a modern look and an old world soul. We craft artisanal dry pasta using the best Italian traditional techniques and 100% organic American flours. True to the Italian pasta makers, Baia Pasta is cold-kneaded, extruded through brass dies, and dried gently at low temperatures. Our small batch pastas have a rough surface and a great al dente texture, creating an exceptional mouthfeel and exalting wheat flavor. We also keep things sustainable by using 100% recycled materials and vegetable inks for our packaging, and by sourcing all materials and ingredients as locally as possible.

Q: What causes the cosmetic issue of the “impastah”?

A: It takes 2 to 3 days to perfect a batch of Baia Pasta. The most sensitive and time-consuming step is drying the noodles. Our pastas are dried at low temperatures for long periods of time, to achieve great texture and preserve the true flavor of wheat, something we’ll never compromise on. However, this gentle drying process requires moisture to be extracted carefully. If the pasta dries unevenly, structural breaks could ruin the pasta aesthetically. In brief, it’s perfectly delicious pasta, in full Baia Pasta spirit, but sadly it might break while cooking. Italians term pasta with this cosmetic issue “bottata”, meaning that the pasta has been punched and beaten up.

Q: How did Baia Pasta get started?

A: The idea of making pasta originated from Renato’s desire to make good food after years of being a passionate advocate for it. Around the end of 2009 or the beginning of 2010, Renato was having conversations with Michael Pollan and Angelo Garo at the Renaissance Forge in SF about good wheat, bread, and beer, and how pasta is somehow forgotten in the picture.

In American culture, mac and cheese tends to be about the cheese, never about the pasta itself. The same goes for pasta sauce — the emphasis is always on the sauce, never on the noodle itself. But, ironically, the U.S actually has the best grains. In Italy, 75% of the grains used to make pasta are foreign, 80% of which come from the U.S.

When Renato talked to me about his ideas, I was on a tenure track at UCSF in Molecular Medicine and wasn’t yet ready to bite, but I eventually did join as a co-founder officially at the end of 2010.

We started very small with tiny machines, loving the idea of being pirates in food, making pasta for a year from essentially a laundry room. We sold our pasta in underground farmers’ markets. Our first bag was purchased by a CHOW editor at the New Taste Marketplace in Potrero Hill.

Shortly after, we began to provide our pastas to local restaurants. Eventually, in late 2011, we moved to Jack London Square. I spent 4 years doing everything I could from a distance, running our website, marketing, and graphics, while Renato stoically ran the everyday business.

I work 18-hour days now, and I am physically more than tired, but I wake up in the morning loving what I do. Renato warned me, “This is not easy.” I’m now fully aware of the challenges, but at the same time on a very dear mission to achieve our goals.

Q: How much has Baia Pasta grown over the last few years?

A: We’ve grown from 500 to 600 pounds a week to 2500. By the end of next year, we’ll be at 4000 pounds at least.

We’re currently discussing expansion. Possibly taking over a recently vacated space next door. We’re conquering Jack London Square!

Q: There are so many food products you could focus on — why pasta?

A: It’s a very personal mission to restore that love for pasta, an Italian tradition, by using the best grains and techniques.

There is a lot of spaghetti around. But we couldn’t find short cuts, such as paccheri or maccheroni, with the quality and variety that we crave. We wanted to bring that variety to the market: real artisanal pasta with a lot of personality, not made from semi-industrial machines.

The moment Renato and I tasted our pasta, we were blown away at what we’d created. We thought, “We made it. We love it. We have to do this. It’s delicious.” A lot of people say we’ve ruined pasta for them — they can’t go back to the other stuff!

Q: How do you ensure you’re getting the best grains?

A: We always go for texture and flavor first.

Our first stop was finding a high quality miller. We went to a miller in Petaluma with access to awesome, 100% organic grains from Utah and Montana — among the best in the U.S. We ordered a few bags and they were delicious. The flavor of the wheat knocked our socks off.

Some folks put the most local grains first, and rightfully so. It is the right message to send. However, we go for taste first. For example, we tried some organic spelt from a local farm in Washington, which was good, but then we tried spelt from a little farther north in Washington, through our miller, and it was phenomenal.

The principles of Slow Food are: good, clean, fair. If it’s not good, don’t even bother with clean and fair. Clean and fair are important, but it has to be good.

At the same time, we have certainly investigated more local varieties of wheat with our miller. Stay tuned, tasty things are coming!

Q: What is the greatest joy of your job?

A: For Renato, I’m pretty sure it is having accomplished an artisanal operation. We’ve put something in motion that didn’t exist before. We’re growing with our employees, growing together; we are a family. He loves the idea of starting something.

For me, I’m more lab-oriented. I love being the operations manager. I love the details of production — having the flour come in, knowing the details from the miller, making the pasta, boxing it. There is a beautiful order in that process.

Both of us thrive off the idea that we’re feeding people. It is the most essential gratification. I know the pasta will land on a table, it’ll make a kid happy, they’ll talk about it and smile and laugh.

Q: What is your favorite food to eat, other than pasta of course?

A: For Renato, it is salumi and cheese. He could sit there and eat that all day. I might join him too.

For me, I love fried chicken so much. I love it breaded more than fried, but fried is amazing. For my 40th birthday last year, I had a party that was fried chicken everything! I also love onions and potatoes. Feed me onions and potatoes and I am the happiest man on earth.